The composition of electronic waste includes many rare and expensive metals, such as indium, gold, cerium and erbium. In addition, they contain other useful elements: aluminum, arsenic, boron, barium, calcium, chromium, copper, iron, potassium, magnesium, molybdenum, sodium, nickel, lead, tin, antimony, strontium and zinc. So, the screens are coated with indium and tin to obtain a touch screen. Most smartphones are equipped with a display made of a mixture of aluminum oxide and silicon dioxide. Additionally, it is tempered with potassium ions to increase its strength. Rarer elements are used to make the display color and resist UV radiation.

Rare metals are now extracted from natural sources, but the proven reserves will last for 20 years. Their content in the source ranges from 0.001% to 0.1%. During extraction, more than 90% of additional impurities remain unused. Thus, by recycling electronics, you can get more useful material and reduce the hazard class of waste. The isolation of a specific metal from the entire flow will allow it to return to the production cycle. The search for answers to environmental challenges is one of the priorities for the Perm REC "Rational Subsoil Use".

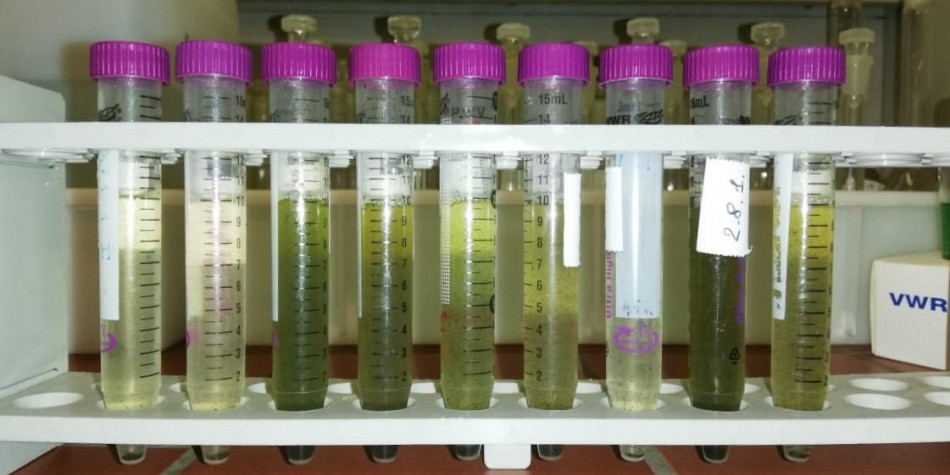

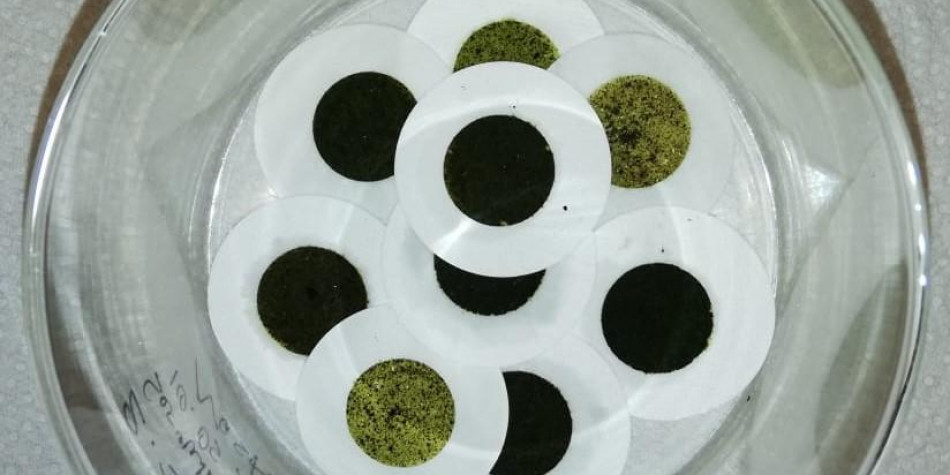

- The average service life of mobile phones and computers is gradually decreasing and now ranges from 2 to 6 years. Then the devices become waste that is recycled very little. We have proposed a method that will allow rare and expensive metals to be returned to the production cycle–" says Anastasia Chugainova, a graduate student of the Department of Environmental Protection of the Faculty of Chemical Technologies, Industrial Ecology and Biotechnology of Perm Polytechnic University. – We leach metals into a solution that needs to be brought to the required pH level. Microscopic algae Chlorella Vulgaris, Chlorella Sorokiniana, Chlorella Spirulina and Scenedesmus sp. absorb them from screens and monitors. Then we burn the algae, and the metals remain in the ash residue. Now we are "teaching" algae to "selectively" extract rare metals. Our group has already determined the necessary conditions for processing screens and extracting metals," explains the biotechnologist.

According to biotechnologists, the development may be of interest to consumers of rare metals - manufacturers of electronic equipment and enterprises of the machine-building and metallurgical industries. In addition, the technology can be used in landfills of municipal solid waste.